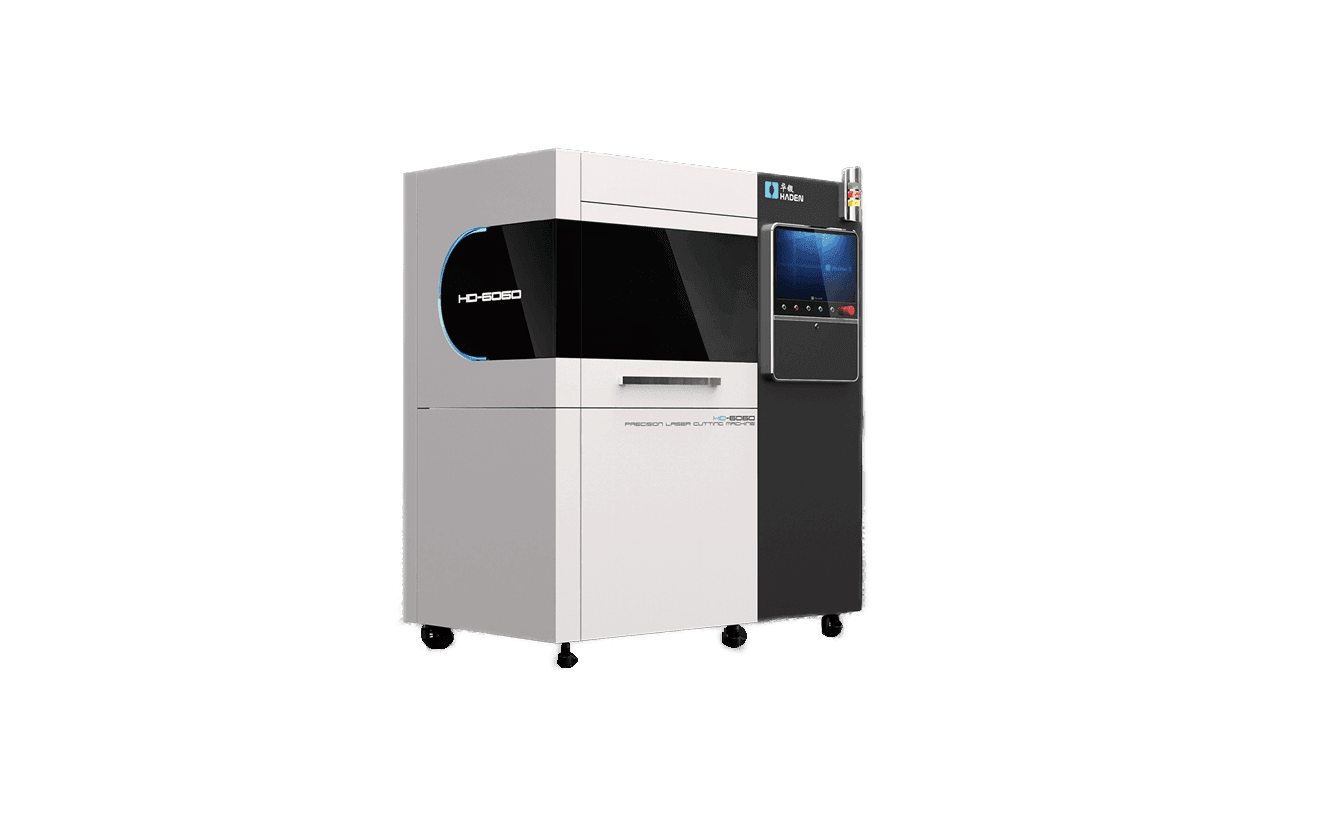

HADEN

Precision fiber laser cutting machine

PRECISION FIBER LASER

PRECISION FIBER LASER CUTTING MACHINE

Mechanical overview

- Fast cutting speed, high work efficiency and high stability. Professional control software, flexible operation, simple and convenient operation

- The large working area eliminates the need for cutting, making it suitable for mass production.

- High precision, more suitable for precision parts processing and cutting of various fine crafts. British-imported YAG laser generator with stable power and strong continuous working ability

- The kerf is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and no subsequent processing is required.

- It uses an imported servo motor and precision guide rails, which ensure high cutting precision, stability and a longer lifespan.

High cutting precision

Laser cutting machine positioning accuracy 0.05mm Repeat positioning accuracy 0.03mm Laser cutting machine narrow kerf The laser beam is focused into a very small spot, so that a high power density is achieved at the focal point. The material is quickly heated to the point of vaporization, and evaporation forms a hole. As the beam and material move relatively linearly, the hole is continuously formed into a narrow kerf. The kerf width is generally 0.10-0.20mm

Laser cutting machine smooth cutting surface

The cutting surface is free of burrs, and the surface roughness of the cut is generally controlled to within Ra6.5.

Laser cutting machine is fast

Cutting speed can reach 10m/min Maximum positioning speed can reach 30m/min Much faster than wire cutting. Laser cutting machine has good cutting quality

Non-contact cutting, the edge is minimally affected by heat, there is basically no thermal deformation of the workpiece, and the collapse edge formed during material punching and shearing is completely avoided. The cutting slit generally does not require secondary processing.

Improve the speed of shipping samples

After the product drawing is formed, laser processing can be performed immediately, and the physical object of the new product can be obtained in the shortest time.

No damage to the workpiece

The laser cutting head does not come into contact with the surface of the material, ensuring that the workpiece is not scratched,

and is not affected by the shape of the workpiece

Laser processing is flexible and can process any graphics, and can cut pipes and other special-shaped profiles.

Laser cutting machines can cut and process a variety of materials

such as plastics, wood, PVC leather, textiles, plexiglass, etc.

Save mold investment

Laser processing does not require molds, so there is no mold consumption, no need to repair molds, and less time spent changing molds, which saves processing costs and reduces production costs. It is especially suitable for processing large products.

Save materials

Computer programming can be used to cut products of different shapes, maximizing the utilization of materials.

Safe and environmentally friendly

Laser processing produces less waste, is low-noise, clean, safe, and non-polluting, greatly improving the working environment.

Laser cutting machines are mainly used for non-contact cutting and perforating of metal sheets and pipes. The minimum cutting slit can reach 0.1mm, which is especially suitable for cutting and perforating materials such as stainless steel sheets, iron sheets, silicon wafers, and ceramic sheets.

Widely used in industries such as precision electronics, decoration, molds, mobile digital, sheet metal and hardware. ullamcorper mattis, pulvinar dapibus leo.

Minimum spot diameter 015MM

Maximum cutting thickness: 6MM ;

Maximum cutting speed: 2000MM/min

Aiming and positioning: red light indication (optional CCD monitoring);

Control system: PC or PLC

Minimum cutting slit: 0.15MM ;

Repeat accuracy: ±0.025MM

Table stroke: 2500xl5005MM ,or customized;

Power consumption: 15KW ;

Power requirements: AC380V/50HZ/60A ;

Overall dimensions: 2750x550xl5700MM ;

Cooling method: water cooling